LDd2 x 314162C When one pulley is larger than the other pulley. This majorly includes Agitator type Agitator dia sweep dia Motor Motor make Mechanical seal Shaft dia Motor power Gearbox Gear box ratio Power Supply type and Motor - Gear box mounting.

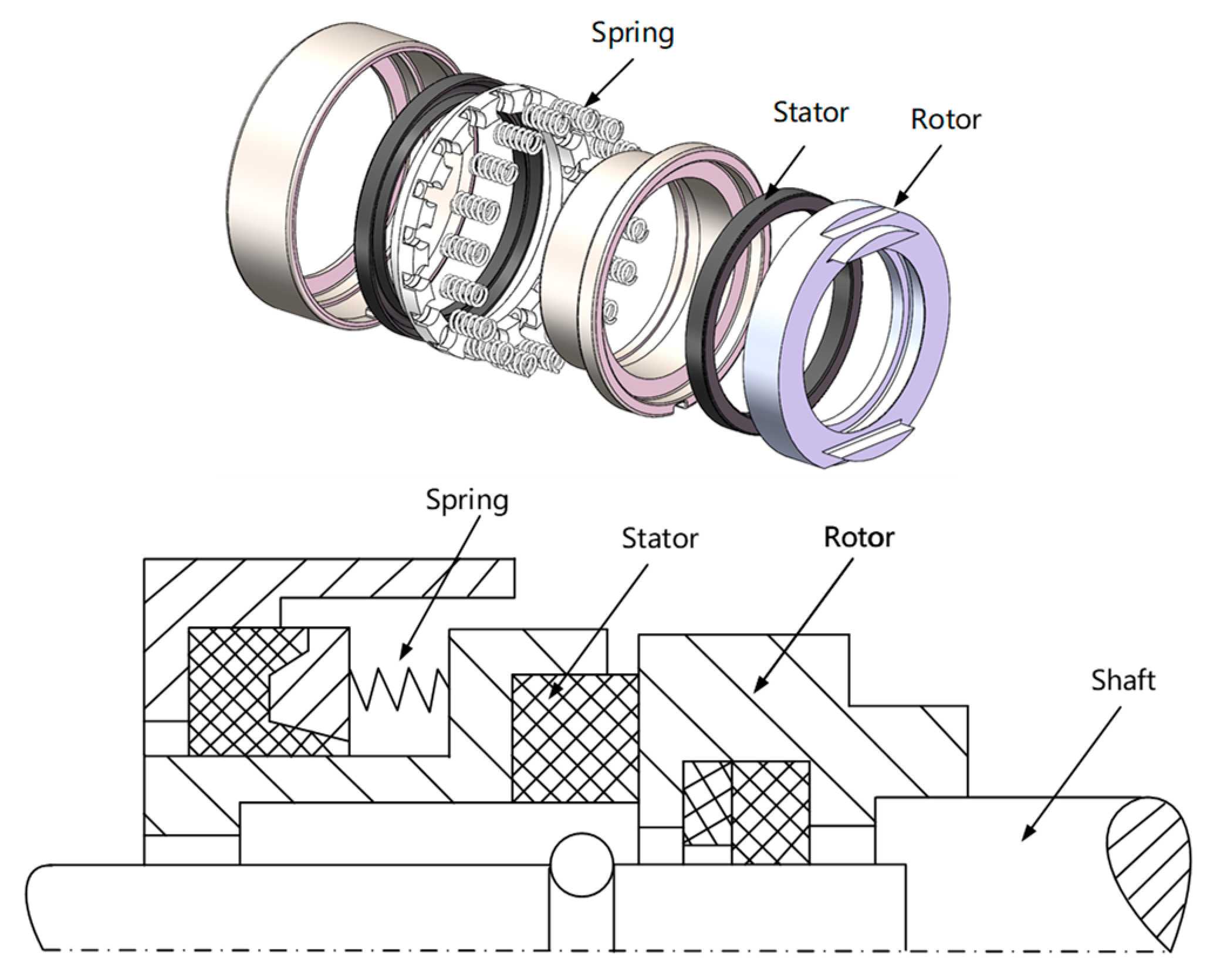

Fundamentals Of Mechanical Seals Seal Faqs

Expressed in feet per minute FPM SD x RPM x 2618 x 1021.

. For more on calculations there are free resources online. Electrical gas mechanical plumbing elevators and conveying systems and boilers Sign permits subject to Sections 105111 and 3107 Foundation and earthwork permits Miscellaneous permits. Some people like Channel because you can bolt directly through it without squishing it.

Agitator Drive details. Track pin seals. One is at.

When the head and tail pulley are the same size. The simpler design. This includes the Design pressure design temperature and the type of welding of the dishes.

Radial shaft seals. Systems or parts thereof should operate only as needed. API Standard 682 PumpsShaft Sealing Systems for Centrifugal and Rotary Pumps FOURTH EDITION MAY 2014 256 PAGES 25500 PRODUCT NO.

When applying for a building. LDd2 x 314162CD-d 2 4c. P G 1 x Cin feetx W in.

The gas seal between the roof and the main digester walls was achieved by submerging the lower edge of the roof in the slurry Figure 22A. Selection of seal design and material. Radial shaft seals with a low cross sectional height.

The mechanical systems should fit the buildings functional use patterns or architectural program as it is often referred to during the architectural design phase of the building. Projection crane and derrick after-hours permits and other activities as determined by the code official. Vessel Jacket Dimensions and support.

At one time when the load is known per square foot. That is a consideration but its also pretty easy to seal the ends with a cap. A more elaborate water seal similar to Figure 22B was included in the original Penn State design but it became filled with slurry creating operational problems and was removed.

Dont like tube because you cant paint the inside. The plan review fees still need to be sent into the plan intake office in the form of a check along with a copy of the plan application. When a space is unoccupied the system should maintain the optimal conditions required to protect the equipment or materials located therein.

Seals for general industrial applications. Common Calculations for Proper Design Belt Length. Metal face seals.

This will ensure the plan review coordinator matches it to the correct construction project. Either is a good choice depending on how and where the trailer will operate. Additional HDS design options.

Seals for heavy industrial applications. The digital documents must bear the seal and signature of the representing design professional.

An Introduction To The Five Key Features Of Good Mechanical Seal Design Reliability Matters

Calculate The Leakage Rate Of A Mechanical Seal Pumps Systems

Energies Free Full Text Multifield Coupling Model And Performance Analysis Of A Hydrostatic Mechanical Seal Html

Fundamentals Of Mechanical Seals Seal Faqs

Bushing Pv Calculations Daemar Inc

Calculate The Leakage Rate Of A Mechanical Seal Pumps Systems

0 comments

Post a Comment